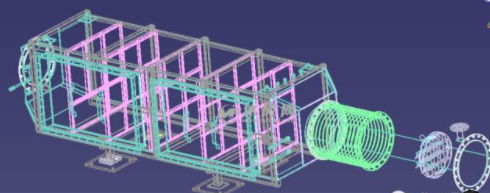

1. Equipment and facilities

Reactor, reactor

1. Abnormal noise of reducer;

2, the reducer or rack oil;

3, reducer plastic wind blade hot melt deformation;

4, the seal, reducer oil shortage;

5, gasket leakage;

6. The antistatic grounding cable is damaged or not installed.

7, the safety valve is not annual inspection, leakage, no account is established;

8, the thermometer is not annual inspection, damage;

9, the pressure gauge is overdue without annual inspection, damage or material blockage;

10, the key reactor does not use double sets of temperature, pressure display, record alarm;

11. The bursting disc has not been replaced, leaked, and no account has been established;

12, the bursting disc lower valve is not open;

13, there is a risk of explosion reaction kettle without bursting disc;

14, the temperature is high, stirring interruption, there is abnormal pressure or punching;

15. The bottom valve is easy to block when discharging;

16, stainless steel or carbon steel kettle acidic corrosion;

17, the loading amount exceeds the specified limit and other overload operation;

18, enamel tank enamel damage is still used in corrosion, flammable and explosive places;

19. The inner tank of the reactor is damaged by erosion at the jacket steam inlet;

20, the pressure vessel exceeds the service life, the manufacturing quality is poor, and the leakage is still after multiple repairs;

21, the pressure vessel has no nameplate;

22, the absence number identification or unclear;

23. The reactor with explosive sensitivity is not effectively isolated;

24, important equipment has not developed a safety check list;

25, important equipment is short of spare parts or standby;

Storage tank, tank farm, tank car

1. The liquid level gauge is fuzzy or damaged or blocked;

2. The electrostatic ground cable is loose or not connected;

3, flange gasket leakage;

4, small platforms and other high storage tanks are not effectively fixed;

5, the safety liquid seal level does not meet the requirements;

6, atmospheric pressure storage tank with pressure use;

7, the loading amount exceeds the prescribed limit;

8, very warm storage tank is not equipped with a thermometer;

9, the container cracks, still in use;

10. The storage tank is damaged by frequent vacuum and nitrogen alternating load;

11, low boiling point solvent or liquefied gas storage tank by direct sunlight;

12, outdoor storage tanks and other transport vehicles and other impact hazards;

13, dangerous goods tank area cofferdam holes are not blocked;

14. The protective dike of the hazardous chemical tank area is not tightly sealed, and rainwater drainage holes are opened arbitrarily;

15. The stop valve leading to the drain pipe is in an unsafe state such as normally open;

16, the flammable or corrosive material outlet pipeline of the hazardous chemical tank area, its support is not set up hanging pressure spring compensation measures, or directly use flexible connection short pipe;

17. There are no warning signs in the hazardous chemical tank area, such as banning mobile phones, banning fire sources, limiting height and speed limits.

18, dangerous goods tank area without leakage, feeding operation record and daily inspection;

19. The tractor enters the dangerous goods tank area at will;

20. There are open fires or forest fires around the dangerous goods tank area;

21, dangerous goods tank operation room using electric stove, electric teapot, electric heating board and other illegal electricity;

22. The tank truck has no grounding device at the loading and unloading site;

23, no measures to prevent the operator from falling from the tank car;

24, not equipped with effective flame arrester and unqualified vehicle condition (light damage or brake failure) tank truck into the tank farm;

25, tank tank safety accessories (pressure gauge, thermometer, safety valve) no inspection date or failure;

26. The tank body of the tank is not marked with the next inspection date of the pressure vessel;

27, no electrostatic drag chain, anti-gas equipment or valve leakage on the tank;

28, grounding before and after unloading is not static for more than 10 minutes;

29. When the tank truck is unloading, the driver and escort leave the unloading site without on-site monitoring personnel;

30, the use of open and splash discharge;

31, make the storage tank exceed the standard level or full material overflow when unloading;

32, vinyl chloride tank truck unloading, hose or flange leakage;

33, vinyl chloride transport when feeding, full tank;

34, the tank car load is not enough many times in the factory transport and discharge;

35. The discharging vehicle is flares off and handbrake braking or starts the vehicle in the middle of discharging;

36, in high-intensity lightning, lightning strikes frequently, engaged in unloading operation;

37, there are no 2 oil tank ground points;

38. When loading and unloading gasoline and toluene, the operator does not wear anti-static overalls and anti-static shoes;

39, liquid ammonia storage tank storage area is not equipped with emergency cofferdams and emergency spray dilution facilities;

40, there is no emergency spray and eye washing facilities;

41, no measures to prevent misloading of materials, such as ethyl acetate into the gasoline tank;

42, standing on the gasoline drum welding;

43, without cleaning, cutting gasoline drums or welding storage tanks;

44, liquid ammonia, vinyl chloride storage tank overloading;

45, tank truck unloading, blocking fire access and occupy the road;

46. The receiving officer leaves the unloading site;

47, loading and unloading site using iron, plastic and other tools easy to generate sparks;

48. The material storage tank sent to the workshop by the tank farm has no operation record;

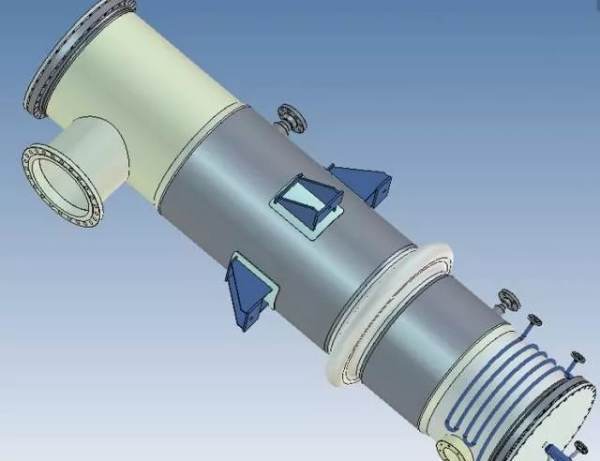

Condenser, reboiler

1, corrosion, gasket aging caused by leakage;

2. The material temperature is too high after condensation;

3, the heat exchange medium layer is blocked by silt and microorganisms;

4, high temperature surface without protection;

5, cooling high temperature liquid (such as 150℃), cooling water inlet and outlet valve is not open, or cooling water is not enough;

6, the evaporator in the first use, rapid temperature;

7, the heat exchanger does not consider anti-shock measures, so that the pipe connected with it is loose due to vibration leakage;

Pipes and fittings

1, the pipeline installation is completed, the internal welding slag, other foreign bodies are not cleaned;

2, the sight glass is not clean or damaged;

3, the selection of cylinder material pressure resistance, temperature resistance, improper installation of the cylinder;

4. The vision cylinder is broken or used with pressure for a long time;

5, anti-static ground cable damage;

6, pipe, flange or bolt serious corrosion, rupture;

7, high temperature pipeline is not insulated;

8, burst control into a bend;

9, pipeline materials and direction of identification is not clear;

10, the pipe color is not clear;

11. The valve connecting different materials is not blind when debugging;

12. Abandoned pipelines are not cleaned up in time;

13, pipe valve installation position is low, easy to bump head or difficult to operate;

14, corrosive material pipelines, flanges and other easy leakage place did not take protective measures;

15, there is the possibility of water, nitrogen, air, steam, etc. into the material pipeline;

16. Iron drums or plastic drums for flammable and explosive materials placed beside high temperature pipelines;

17, pipe or pipe fittings material selection is unreasonable, easy to corrosion;

18, glass tube level gauge no protective measures;

19. No protective metal mesh is installed at the sight glass that may explode;

20, the check valve can not operate flexibly or fail;

21, electric valve power failure, pneumatic valve stop gas;

22, the use of hydrogen and other pressure pipelines without regular maintenance or disease operation;

23. When using pressure pipes, the operator is not trained or licensed;

24. Maintenance personnel are not qualified to repair and transform pressure pipelines;

25, the pressure pipeline welding quality is poor, there are biting edge, porosity, slag, welding defects such as incomplete welding;

26, the pressure pipeline is not in accordance with the provisions of the safety accessories or safety accessories overdue is not verified;

27, the pressure pipeline has not established files, operating procedures;

28, glass lined pipe by steel pipe impact;

29. The existing pipeline valve is still used after the production process medium is changed without considering the material adaptability;

30. Nitrogen pipe and air pipe are connected in series;

31. The brine pipe is connected with the cooling water pipe in series;

Conveying pump, vacuum pump

1, pump leakage;

2, abnormal noise;

3. The coupling has no protective cover;

4, pump outlet is not equipped with pressure gauge or check valve;

5. When long-term disuse, the liquid in the pump and pipeline is not discharged, causing corrosion or freezing;

6. When the positive displacement pump is running, the outlet valve is closed or the safety return valve is not installed;

7, pump inlet pipe diameter is small or pipe length or bend more;

8, centrifugal pump installation height is higher than the suction height;

9. No anti-static belt is used;

centrifuge

1, filter solvent, not filled with nitrogen or nitrogen pipeline blocked or no flowmeter on site can be displayed;

2. When the centrifuge is used to filter the solvent in the fine drying package, the oxygen meter and alarm device are not installed;

3. Brake quickly or brake with auxiliary tools (such as iron bars, etc.);

4, the centrifuge is not effectively grounded;

5. No anti-static belt is used in the explosion-proof area;

6, centrifuge running, abnormal vibration;

Double cone (Double cone rotary vacuum dryer)

1, no guardrail and safety chain device;

2. Personnel climb into the double cone to replace the vacuum bag;

3, the transmission belt without protection;

4. Shaft seal leakage;

5. The vacuum pipe is blocked or the vacuum valve is not opened when used;

Gas bottle

1. The gas cylinder has no bottle cap and shock-proof ring;

2. When hydrogen cylinders are transported and stored in summer, there are no shading measures, resulting in exposure;

3. Some gas cylinders exceed the annual inspection period;

4, acetylene cylinder and oxygen cylinder used at the same time, the safety distance is not more than five meters;

5. Close the hydrogen bottle valve with gloves with catalyst;

6, knock the collision cylinder;

7. After the cylinder is used, the air pressure is less than 0.05Mpa;

8, gas cylinder group and pipeline connection, valve damage;

9. When the hydrogen bottle is used, the anti-static device is not used or is broken;

10, the gas cylinder has no anti-toppling measures;

11. There are ditches and secret tunnels in the storage place;

12, the storage place is not ventilated or poorly ventilated or corrosive gas enters;

13, lack of fire extinguishing equipment;

14, acetylene cylinder put down to use;

15, the color of the gas cylinder is blurred;

Second, electrical instruments

1. Non-explosion-proof electrical appliances or control cabinets are set up in the explosion-proof area;

2. The window glass of the power distribution room is broken;

3. There are more sundries in the distribution room;

4, there are steam water, material pipes, dust, corrosive substances in the power distribution room, resulting in aging of the electrical equipment in the cabinet, resulting in short circuit accidents;

5, transformer outdoor acid fog corrosion or solvent infiltration or dust;

6. Clothes and other sundries behind the control cabinet or transformer cabinet;

7, the distribution cabinet is too old, easy to produce short circuit;

8, the cable is close to the high temperature pipeline;

9. Material pipes and sewage pipes around the overhead cable leak, causing corrosive materials to flow into the cable bridge;

10. Buried cables are corroded by underground water;

11, cable well, ditch sewage infiltration;

12. Cable bridge is seriously corroded;

13, cable protection sleeve aging fracture;

14. Cables or steel pipes laying electrical lines are not strictly blocked with non-combustible materials when they pass through holes in the walls or floors between different places;

15, random pull activity exhaust, resulting in cable joint fall off, leakage;

16, switch button corresponding equipment bit number identification is not clear;

17. There are random and unknown cables in the workshop;

18, emergency lighting is not installed or broken;

19, open-air motor without protective cover;

20, the operation site lighting is not enough;

21, the equipment is not matched with the electrical (calf trailer, old cow trailer) electrical equipment heat damage, fire;

22, electrical equipment, cable bridge flush;

23, explosion-proof mirror lamp, lamp Yuanbao screw loose, light leakage;

Third, static electricity

1. In inflammable and explosive places, the reactor, pipeline, storage tank, condenser, conveying pump, flange, valve is not grounded or not badly grounded;

2. In flammable and explosive places, the powder hopper is not grounded and filled with nitrogen;

3, exceed the safe flow rate (v2<0.64/d) to transport gasoline, toluene, cyclohexane and other liquids;

4, hydrogen flow rate of the main pipe more than 12m/s, branch pipe more than 8m/s;

5, the gasoline from the high level into the bottom of the tank or the ground;

6. When nitrogen is not filled, aluminum isopropyl alcohol and magnesium powder are put into the reactor containing gasoline and toluene through the open funnel;

7, in flammable and explosive places, wear and take off clothes, shoes and hats and strenuous activities;

8, in flammable and explosive places, with chemical fiber material mop or rag scrub equipment or ground;

9, fill the plastic bucket with gasoline;

10, with gasoline and other solvents to wash the work clothes or mop the floor or steel platform, ground;

11. Stainless steel and carbon steel tank walls are not grounded with welded steel bars or flat steel, and there are no two grounded places over 50m2;

12. In places where flammable and explosive gases are distributed, humidification and other measures to eliminate electrostatic hazards are not adopted;

13. Use plastic pipes to suck or fill toluene or recycle toluene;

14. Use compressed air to transport or stir gasoline;

15. Anti-static slippers are not used in explosion-proof clean areas;

16, grounding flat steel, roof lightning belt rust, serious corrosion;

17, the metal equipment above the roof of the unwelded steel bar into the lightning protection belt;

4. Production site

1, storage of raw materials or waste more;

2, the scene "running, bubbling, dripping, leaking" more;

3, the insulation layer is damaged;

4, lack of effective protective guardrail;

5, normally closed fire door usually open;

6, there are dust (magnesium powder, zinc powder, etc.) operating positions, not cleaned up in time;

7, metal sodium, sodium hydrogen storage, no rain prevention measures or waste buckets, waste bags at will;

8. Blocked fire passage or various pipelines and their supports obstruct passage;

9, fire extinguishers lack or expired rust or fire belts, fire hydrants do not meet fire requirements;

10, waste bucket has multiple labels;

11, strong oxidants (hydrogen peroxide, potassium permanganate, etc.) stacked on the wooden frame;

12, the steel platform shaking amplitude is too large;

13, steel platform or steel column corrosion is serious;

14, the solvent concentration in local areas exceeded the standard;

15, high valve handle, iron bar, easy to fall;

16, the concrete floor vibration is large;

17, outdoor steel shed or roof debris;

18. The anti-gas equipment is expired or invalid;

19, production site storage of non-production utensils (food, newspapers, novels);

20, the lack of summer heat prevention and cooling facilities;

21, outdoor small pipe pipe is not insulated in winter;

22, there is no emergency shower, eye wash and other health facilities in the workshop or have been damaged;

23, the vehicle does not install flame arrester into the production site;

24, flammable and explosive places are not installed combustible gas alarm or failure;

25, the reactor, storage tank, pump and other equipment is not marked the position number and name;

26, the big iron door is not fixed bolt, once the wind may make the iron door wipe out sparks, leading to danger;

27, the warehouse threshold is low, once an accident occurs, dangerous goods will spill;

28, production site ground storage iron plate, steel pipe;

5. Personnel and on-site operation

1. No post operation record or incomplete operation record;

2, suction, filling, handling corrosive items without wearing protective equipment;

3, there are operators off the post, leave the post, sleep and other phenomena;

4, powder and other feeding posts do not wear dust masks;

5, quick switch valve;

6. Stratified kettle and bottom valve are not closed after stratification;

7, stratified kettle, tank water valve open too large, resulting in water oil into the sewage tank or drainage time is too long forget to close the valve and run material;

8, high temperature kettle, tower into the air;

9. The extraction catalyst (such as palladium carbon, active nickel, etc.) is scattered more on the site;

10. Use an iron rod to poke the blocked materials in the pipeline and kettle or use non-explosion-proof instruments to generate sparks;

11. No ear protector or earplugs in noisy environment;

12, storage tank overpressure use;

13, where gasoline, toluene and other flammable and explosive solvents are used, the kettle and tank are not replaced with nitrogen;

14, smoke diffuse, poor ventilation or hypoxia;

15. Open the reactor cover with pressure;

16, employees have occupational taboos or allergies or contact toxicants for a long time;

17, emergency valve or emergency switch is not easy to operate;

18, in flammable and explosive places, wear shoes with nails or high heels, sandals;

6. Civil construction

1. There are no preventive measures (such as blocking with fire-retardant materials) for upper and lower floor pipe Wells where fire may spread;

(2) The process with explosion risk does not use explosion-proof walls and light roofs or does not consider enough blasting surface;

3, the design number of entrances and exits and emergency channels is not enough or blocked or there is no obvious sign;

4. The foundation of the plant has been corroded by acid and alkali substances, and the columns and beams have been seriously damaged;

5, when there is strong wind, the steel window glass is easy to fall off;

6, the stairs are too narrow or steep;

7, indoor drainage is poor or low-lying long-term water, oil accumulation;

8, the channel or operation, the head and ceiling do not have enough space;

9, in the case of unknown underground pipelines (water pipes, cables, etc.), the road is excavated at will;

10. Use large machinery to dig soil near underground cables, pipelines, etc.

11, when the fire in the no-fire area, the production workshop is not sent to monitor;

12, the construction of abnormal conditions (pipeline fracture, leakage, etc.), did not immediately stop for emergency treatment;

13, dug trenches, pits, pools, etc., and damaged pipelines, no fences and signs, no lighting at night;

14, found that the soil is likely to collapse or slide, did not stop the operation;

15. There are no measures to prevent underground empty tanks and pools from floating;

16. When working in the tank and pool, the corresponding approval procedures are not handled or the approval requirements are not implemented (such as labor insurance supplies, guardian implementation, etc.), and the preventive measures are not in place.

17, in the non-civil construction operations, do not go through the "non-infrastructure employment procedures" or do not understand the corresponding possible risks before the operation, in the case of inadequate safety measures to start;

Seven, production maintenance

1, cleaning and maintenance in the container, encounter dangerous situations, there is no emergency escape facilities or measures;

2, hot work without guardian or guardian by new employees or illegal fire;

3, overload lifting;

4. Tools or lifting objects are not reasonably fixed;

5, not equipped with or wear protective equipment (safety hat, seat belt, etc.);

6, no warning signs or signs have been blurred (such as preventing electric shock, preventing falling objects, etc.);

7. Step on the suspended pipe or small pipe diameter plastic pipe and glass lined pipe or use unsafe climbing facilities during maintenance;

8, welding machine, manual electric tools and other cable damage caused by leakage, zero line damage or jumper;

9, blindly enter the sewage pool, deep ditch, deep pool operation;

10, winter pipe frame ice slip, no anti-slip measures;

11. The welder of the installation company has no welding certificate or the inspection worker has not undergone relevant training;

12, directly stand on the roof of fragile materials such as asbestos tile, linoleum work;

13. When working at heights, no preventive measures were taken for cross operation;

14. When working at a height, the neutral line of the welding machine is not connected to the welding position;

15, smelly or may produce toxic gases in the area of operation without wearing a gas mask;

16, high repair, digging holes in the wall, no security fence or safety net;

17. The hazardous materials cleaned out are scattered from the upper level to the lower level;

18, with lifting machinery manned;

19, night operation without enough lighting;

20, in case of strong winds above six or other bad weather, still work at high altitude in the open air;

21. When working in the kettle, there are no more than two guardians outside the kettle;

22. When the kettle is repaired, the power supply is not cut off and the sign of "maintenance, no closing" is hung;

23, before the tank operation, the kettle is not effectively cleaned;

24, Before the tank operation, the concentration of combustible gas, oxygen content, toxic gas (CO, H2S) concentration was not analyzed;

25, before the tank operation, the material pipelines such as raw materials, solvents, steam, water, nitrogen and other pipelines are not reliably isolated;

26, during the maintenance process, no regular sampling analysis of the kettle;

27. The sign of "Someone in the tank" is not hung in the obvious position outside the kettle;

28. The "double inspection system" was not implemented during the canning operation;

29, the kettle lighting does not meet the safety voltage standard, the voltage is greater than 24V under dry conditions, and the voltage is greater than 12V under wet conditions;

30, the maintenance is completed, no inspection, clean up the debris on the boot use;

31, a long time in the kettle operation is not rotated;

32, maintenance, the kettle lacks the necessary ventilation facilities;

33. Weld the outer wall surface or inner wall of the glass lined tank;

34, into the glass lined kettle, groove is not laid soft cushion;

35, rapid heating or rapid cooling glass lined kettle;

36. When the glass lined tank is used, the bolt or clip of the tank mouth or manhole falls into the kettle;

37, the use of glass lined kettle, stainless steel kettle, carbon steel kettle, acid into the jacket;

38, the selection of materials without temperature, PH, corrosion solubility audit, there may be pressure occasions without pressure special audit;

39. After the overhaul, all the Spaces in the kettle and the maintenance site, such as high and low positions, have not been fully cleared and reviewed, and trial operation has begun;

40, the overhaul is completed, the relevant matters are not fully communicated, the change is not confirmed and approved, and the relevant personnel are not fully trained and understood to take over;

41. The maintenance is put into production without operation confirmation;

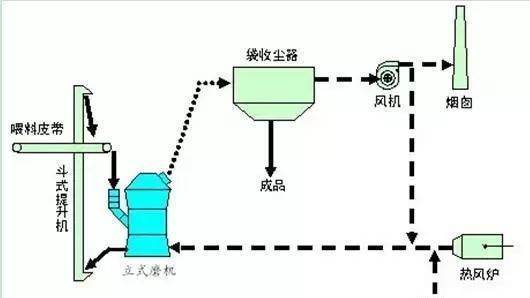

8. Production process

1, there are sudden reactions, lack of countermeasures and training;

2, freely change the feeding amount or feeding ratio;

3, improve the process or new process, no safety assessment;

4, the process changes have not been strictly reviewed and approved;

5, the process is operated within the explosive limit of combustible gas;

6. When using highly toxic materials, use open operation;

7, did not write the process operating procedures for trial production;

8, did not prepare the material properties of the material and safety precautions;

9, when the material used is decomposed, the heat generated has not been calculated in detail;

10, there is a potential risk of dust explosion;

11, a certain raw materials can not be put into time, there is danger when the material in the kettle is temporarily stored;

12, raw materials or intermediates in storage will occur spontaneous combustion or polymerization or decomposition risk;

13. Various parameters (temperature, pressure, etc.) in the process are close to the danger limit;

14, when abnormal conditions occur, there is no measure to quickly discharge the reactants;

15. There are no measures to prevent and stop rapid reactions.